Impact Pitches at CLIMAFIX Summit 2025 | Li Circle

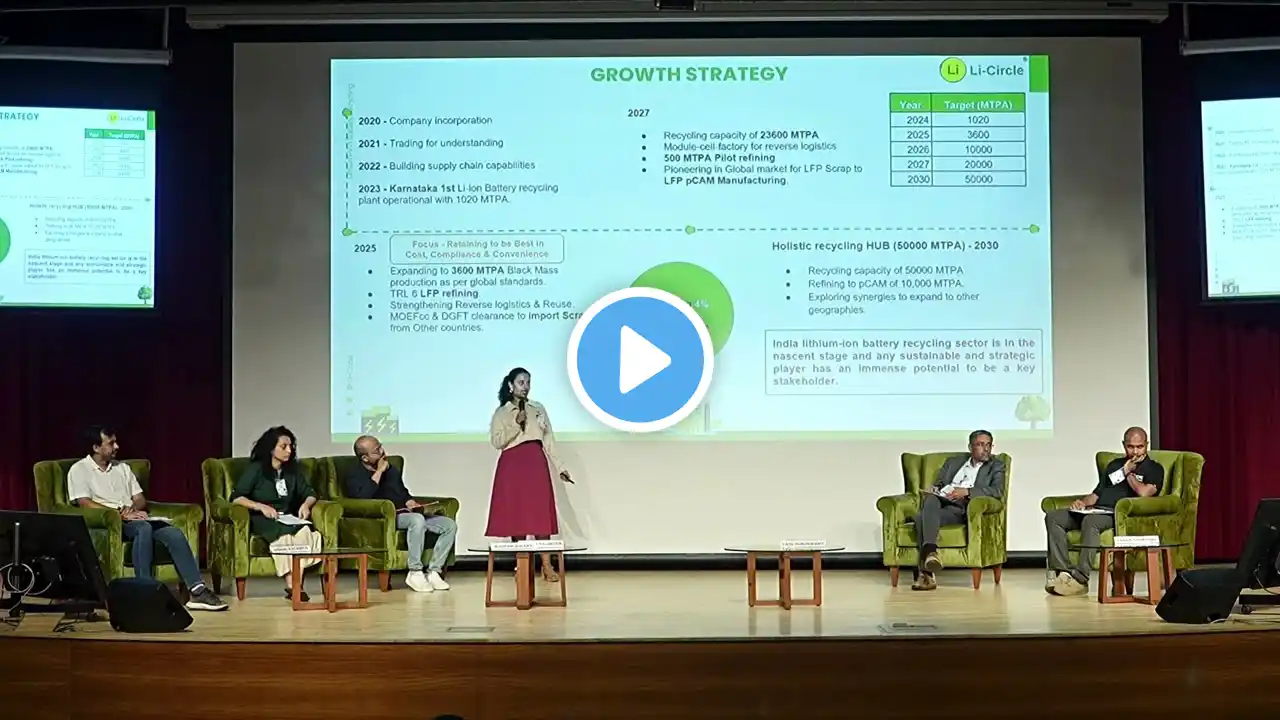

In this Impact Pitch at CLIMAFIX Summit 2025, Sri Harini Senthilkumar (Li Circle) presents Li Circle’s mission to make lithium-ion battery recycling green, clean, and sustainable, with a focus on direct recycling of LFP (Lithium Iron Phosphate) batteries. Li Circle addresses a major challenge: traditional hydrometallurgical recycling consumes large amounts of chemicals, water, and energy, while generating significant carbon emissions and high processing costs. Their direct-recycling approach reduces environmental impact by eliminating harsh acids, minimizing water use, and recovering materials at battery-grade purity levels with far lower processing cost. The company operates a pilot-scale facility that collects end-of-life batteries and production scrap from EV manufacturers, cell makers, and OEMs. After multi-stage mechanical processing, they extract black mass, which is being further developed into reusable cathode materials (Pre-CAM and CAM), enabling true circularity for LFP batteries. This pitch covers their technology, unit economics, supply chain strategy, and the path toward scaling up to 50,000 metric tons per year. Speaker: Sri Harini Senthilkumar – Li Circle Session: Impact Pitches – CLIMAFIX Summit 2025 Timestamps: 00:00 – Introduction to Li Circle 01:00 – Team overview and expertise 01:20 – Global and India lithium-ion battery demand trends 01:47 – Problem: lack of sustainable recycling methods 02:21 – What Li Circle does: sorting, grading, and processing EOL batteries 02:46 – Current operations: mechanical processing to produce black mass 03:15 – Why direct recycling is ideal for LFP chemistry 03:41 – Material outputs: Pre-CAM and CAM for cell manufacturing 04:18 – Advantages over hydrometallurgy: lower cost, no harsh acids, reduced emissions 04:54 – Company timeline, pilot plant, and scale-up target (50,000 MT/year) 05:27 – Q&A: Reverse logistics and falling lithium prices 05:56 – Supply chain partnerships with OEMs and battery manufacturers 06:15 – Unit economics resilience through direct-recycling efficiencies 06:55 – Purity targets and alternative applications for lower-grade LFP outputs 07:22 – Q&A: TRL-6 status and processing cost projections 07:39 – Closing remarks Keywords: battery recycling, LFP recycling, direct recycling, lithium-ion circular economy, black mass processing, sustainable recycling, EV batteries India, Li Circle, climate tech India, CLIMAFIX Summit, energy storage materials, battery supply chain sustainability.