One Factory Girl’s Simple Idea Tripled Ammo Production — and Changed WWII Forever

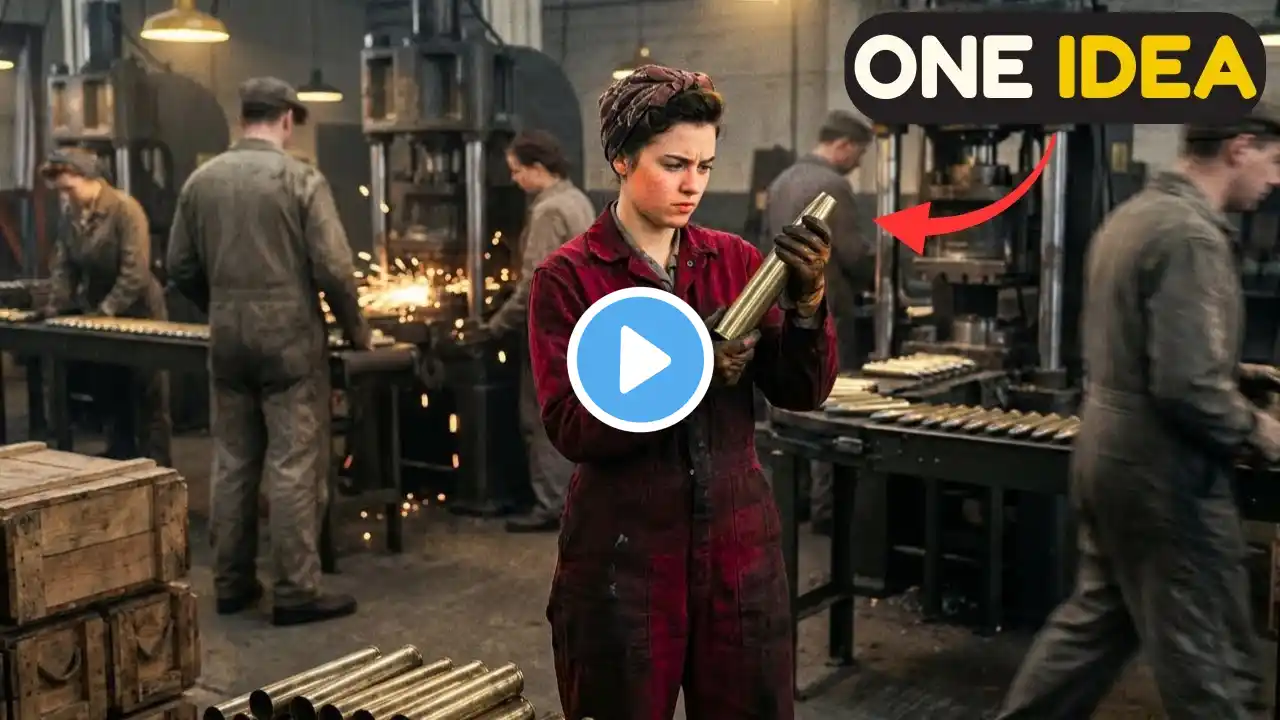

One Factory Girl’s Simple Idea Tripled Ammo Production — and Changed WWII Forever At 0710 on a sticky July morning in 1943, the Lake City Ordnance Plant outside Independence, Missouri, was already trembling under the force of its own machinery. Long rows of stamping presses slammed brass into cartridge cups. Heat poured off the annealing furnaces. Conveyor belts rattled nonstop. The air was thick with metal, oil, and sweat. The United States needed ammunition on a scale no country had ever produced before. Commanders in the Solomons reported firing through hundreds of thousands of rounds in a single week. Infantry units pushing through Sicily were asking for more. Fighter squadrons over Europe burned through .50-caliber belts so quickly that ordnance officers joked it took more ammunition to keep a B-17 flying than it did to build one. Demand had no ceiling, and the numbers were brutal. Washington calculated that sustaining simultaneous campaigns in the Pacific and the Mediterranean required about 2.4 billion rounds each month. At that moment, production was barely reaching half that figure. Inside the plant, nineteen-year-old Evelyn Carter pushed her cart of brass casings toward Line Four and tried not to dwell on the math. Workers murmured about it during coffee breaks. Combat reports all told the same story. Units at the front were rationing ammunition, not because supply lines had failed, but because America simply wasn’t producing enough. Evelyn had been here only twelve weeks, but she felt the weight of it. She saw supervisors studying production charts clipped to boards. She heard engineers grumbling about choke points. And she noticed something else, something the foreman seemed reluctant to acknowledge. The most fragile step in the process—the moment raw casings had to be guided into alignment tracks before charging and crimping—was still done by hand, following a repetitive routine unchanged since 1918. By 0720, the next shift was fully in place. Six women stood at the feeder table, their arms moving in tight, practiced loops. Pick, place, slide. Pick, place, slide. Three motions, repeated thousands of times an hour. The target for this line was 30,000 fed casings per hour, but most days it topped out at 23,000. Spread across the entire plant, that shortfall meant millions of rounds missing every day. One broken nail, one slip, one jammed guide rail, and the whole sequence stopped cold. Evelyn learned fast that the real enemy inside a wartime factory wasn’t sabotage or bad metal. It was time—lost seconds. At 0726, a guide rail broke loose and casings spilled across the floor. Production halted. A red warning light flared overhead. Supervisors rushed in. Mechanics rolled carts into place. The women stepped back, wiping sweat from their faces. They all knew the routine. Every stoppage required recalibration. Every recalibration meant fewer rounds produced. Somewhere in the Pacific, a Marine machine-gun crew was firing faster than Lake City could replace the ammunition. #WW2Records #WW2Tales #WarChronicles #WW2AndWW2Heroes #TalesOfValorPodcast #WW2Legacy #WW2VaultOfSecrets #PatriotWars #WW2ERA #WWMemories #WW2Memories #5MinutesThatChangedHistory