Slab concreting casting.#live #shorts #livestream #livestreaming #shortvideo

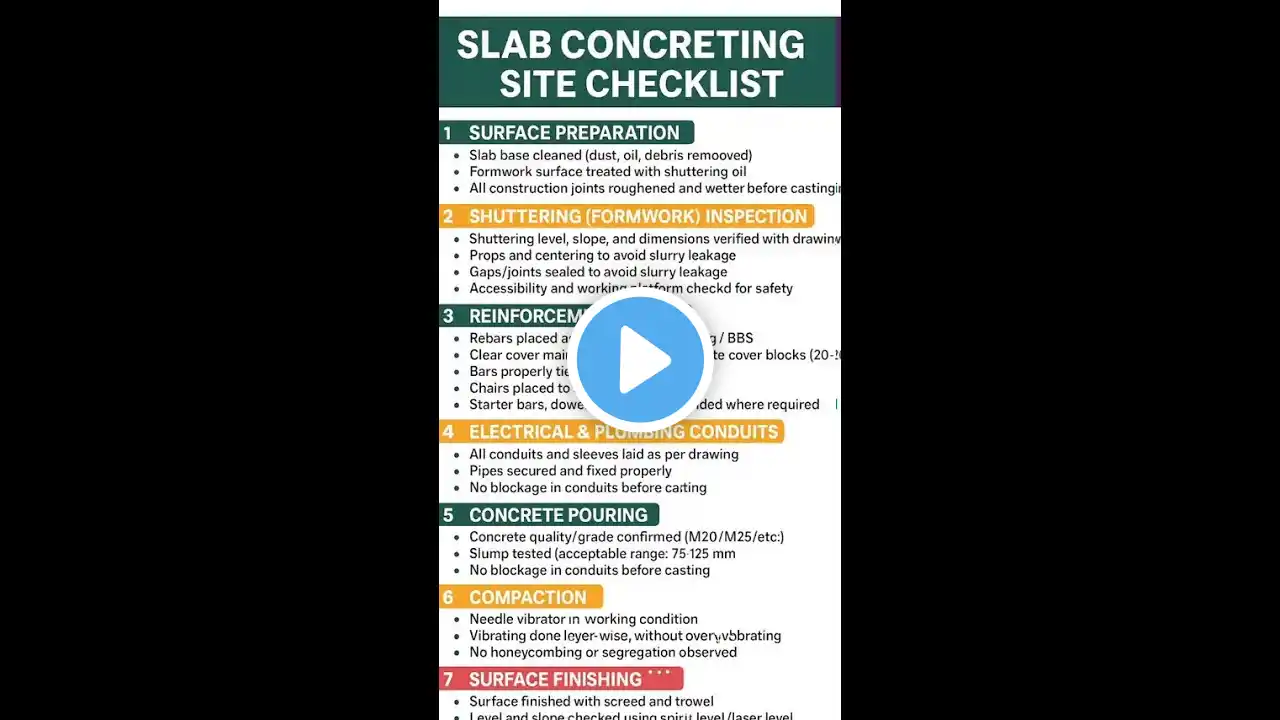

What is a Grade Slab in Building Construction? Grade slab is a concrete slab that is constructed directly on the ground level (earth's surface). It acts as the floor of the building at the plinth level (ground floor), resting either directly on soil or on a layer of base material like compacted sand, gravel, or lean concrete. 🔍 Importance of Grade Slab It serves as the base floor of the building. Transfers load to the ground beneath. Provides protection against moisture and termites. Prevents movement of soil underneath due to heavy load. 🧱 Step-by-Step Process of Grade Slab Construction (Detailed) 1. Site Clearing and Preparation 🔧 Work Done: Remove vegetation, roots, debris, and loose soil. Excavation (if needed) to reach the design level (usually 150–300 mm below plinth). Remove soft or weak soil and replace with good soil if necessary. 🔍 Objective: To create a stable, clean, and leveled working base for further construction. 2. Marking and Layout 🔧 Work Done: Mark the slab area as per drawings using line dori or chalk. Mark locations of columns, walls, and beams if they intersect the slab. 🔍 Objective: Ensure accurate dimensions and alignment for slab casting. 3. Compaction of Subgrade Soil 🔧 Work Done: Use mechanical compactors (plate compactor or roller) to compact the subgrade. Achieve required soil bearing capacity. 🔍 Objective: Prevent settlement or cracking of slab due to weak soil base. 4. Anti-Termite and Waterproofing Treatment 🔧 Work Done: Spray anti-termite chemical (like Chlorpyrifos) on the compacted soil. Lay a polythene sheet (200–250 micron thick) or bitumen sheet as a moisture barrier. 🔍 Objective: Protection against termite attack and rising dampness from below. 5. PCC (Plain Cement Concrete) Layer 🔧 Work Done: Lay a PCC layer of M7.5 or M10 grade (75–100 mm thick). Level and cure for at least 24 hours. 🔍 Objective: Provides a flat, clean, and strong surface for reinforcement placing. Acts as a blinding layer over soil. 6. Fixing Formwork (If Required) 🔧 Work Done: If slab has boundaries or drop edges, provide side shuttering. Ensure leak-proof formwork with adequate bracing. 🔍 Objective: To retain concrete and maintain slab dimensions. 7. Reinforcement Work 🔧 Work Done: Place steel bars as per structural drawings. Maintain cover using concrete cover blocks (20–25 mm). Tie steel bars using binding wire (8 or 20 gauge). Reinforcement Includes: Main bars and distribution bars (usually in 2 layers). Additional steel at column junctions or openings. Provide mesh if required. 🔍 Objective: To handle tension and prevent slab cracking. 8. Conduits for Electrical/Plumbing (Optional) 🔧 Work Done: Place conduits or sleeves for pipes, drainage, or electrical work before concreting. 🔍 Objective: Avoid chiseling slab later and reduce damage risk. 9. Concrete Pouring 🔧 Work Done: Use M20 or higher grade concrete for residential construction. Pour concrete evenly, vibrate using needle vibrator to remove air gaps. Finish the surface with trowel or float. 🔍 Objective: Create a uniform, compact, and crack-free slab. 10. Curing g Work Done: Keep slab surface moist for 7–14 days. Use gunny bags or water ponding for effective curing grade slab construction what is grade slab grade slab grade slab in building construction types of slabs plinth level slab ground floor slab concrete slab on ground grade slab step by step grade slab process grade slab thickness grade slab reinforcement PCC for grade slab anti termite treatment in construction concreting on ground grade slab details construction of grade slab formwork for grade slab steel placement in slab building construction slab civil engineering slab foundation slab plinth beam and grade slab floor slab construction types of concrete slabs grade slab vs plinth beam grade slab in residential building m20 concrete slab m10 pcc in grade slab grade slab shuttering shuttering for ground floor slab steel binding in slab vibrator use in slab how to cast grade slab grade slab slab how to prepare grade slab soil compaction for slab subgrade compaction grade slab layout slab curing grade slab curing time polyethylene sheet in slab moisture barrier slab building construction step by step civil site engineering site engineer daily work civil site work slab casting how to do slab work construction slab base construction slab foundation house construction slab house base slab footing to slab slab casting steps pcc under slab pcc vs rcc concrete slab construction slab work floor slab details how to pour slab site preparation slab civil engineering tutorial learn civil engineering slab for beginners slab kaise banaye civil work explanation grade slab procedure slab construction in India slab construction method construction process grade slab step by step slab casting slab construction in hindi slab construction time minimum slab thickness plinth beam plinth level concrete slab work