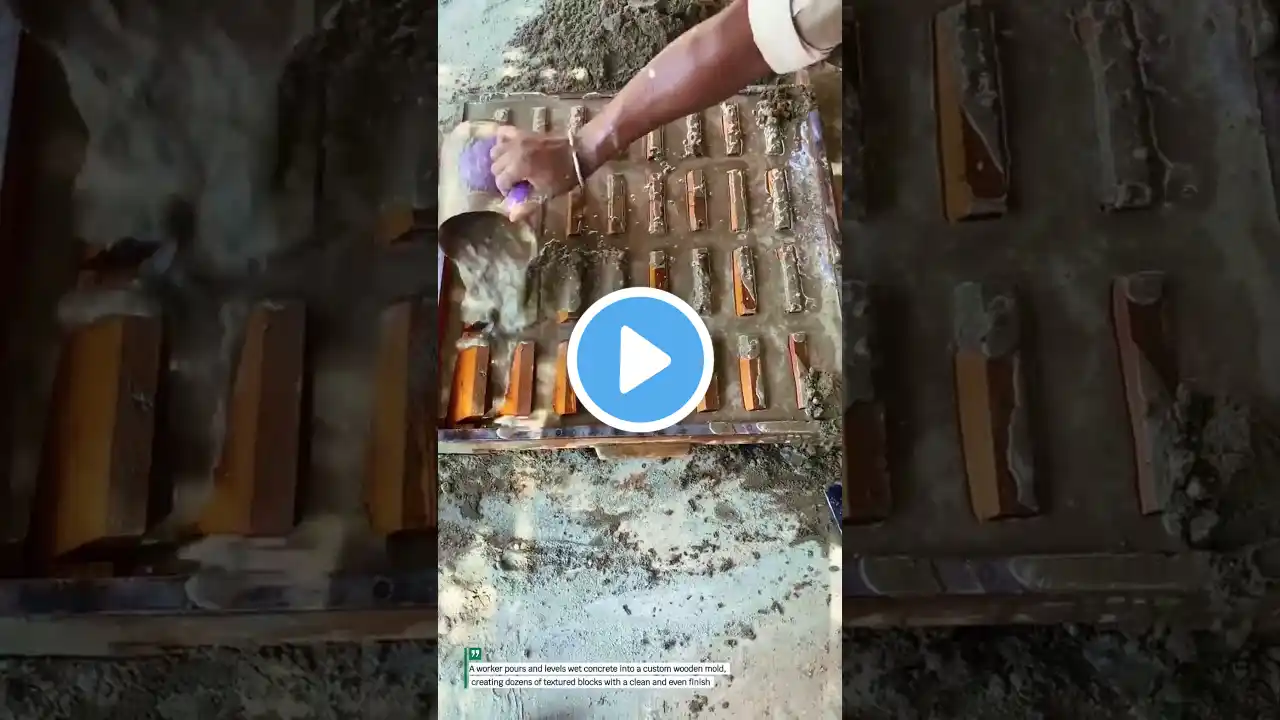

Satisfying Concrete Casting Process | Decorative Paving Mold Making

TITLE: Satisfying Concrete Casting Process | Decorative Paving Mold Making DESCRIPTION: This video shows the concrete casting process using a decorative mold to create patterned paving stones. The process starts from mixing cement, pouring it into the mold, leveling the surface, and allowing it to set into a solid decorative concrete slab. This type of paving is commonly used for yards, pathways, and outdoor flooring. We apologize for any lack of information. We are only ordinary humans trying to share useful knowledge. VIDEO SUMMARY: This video demonstrates how decorative concrete paving is made manually using a patterned mold and cement mixture. SPECIFICATIONS: Material: Cement, sand, water Mold type: Decorative patterned mold Process: Manual casting Application: Outdoor flooring, yard paving, pathways ADVANTAGES: Low production cost Attractive decorative patterns Can be made manually Suitable for small-scale production DISADVANTAGES: Requires drying and curing time Manual process takes longer Mold quality affects final result WORKING PRINCIPLE: Cement mixture is poured into a decorative mold, leveled evenly, and left to harden. After curing, the mold is removed to produce a patterned concrete slab. PRODUCTIVITY IMPACT: This method increases productivity by allowing repeated use of molds and faster production compared to traditional stone carving. KEYWORDS: concrete casting, paving mold, decorative concrete, cement work, manual paving TAGS: concrete casting paving mold decorative paving cement process manual concrete satisfying process HASHTAGS: #ConcreteCasting #PavingMold #DecorativeConcrete #CementWork #SatisfyingVideo