Bar Bending Schedule #Formulas | #Shorts #BarBendingSchedule #Construction

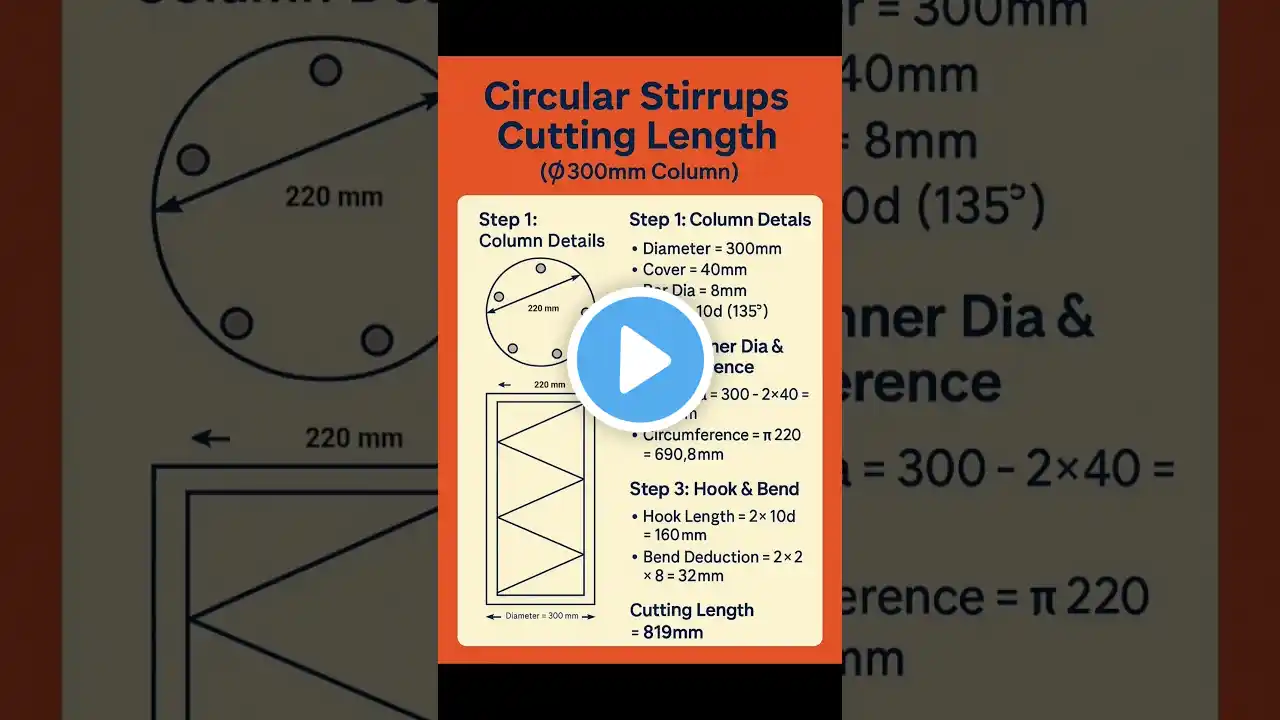

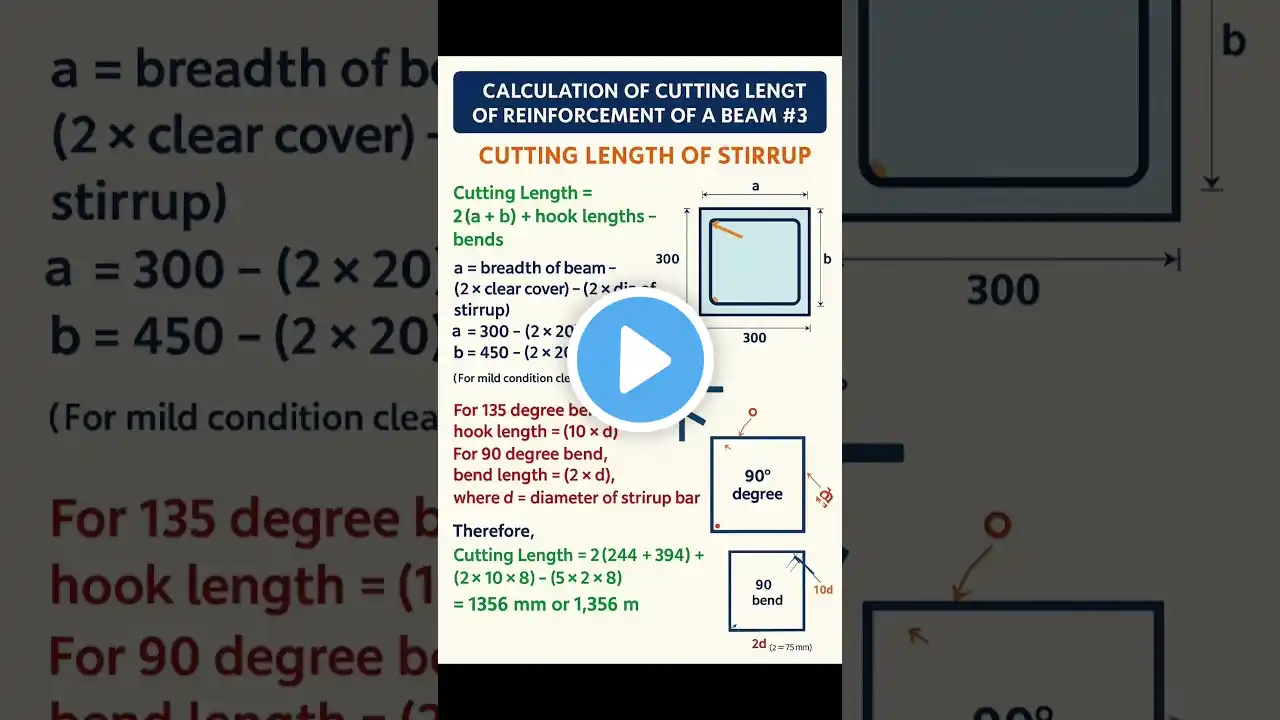

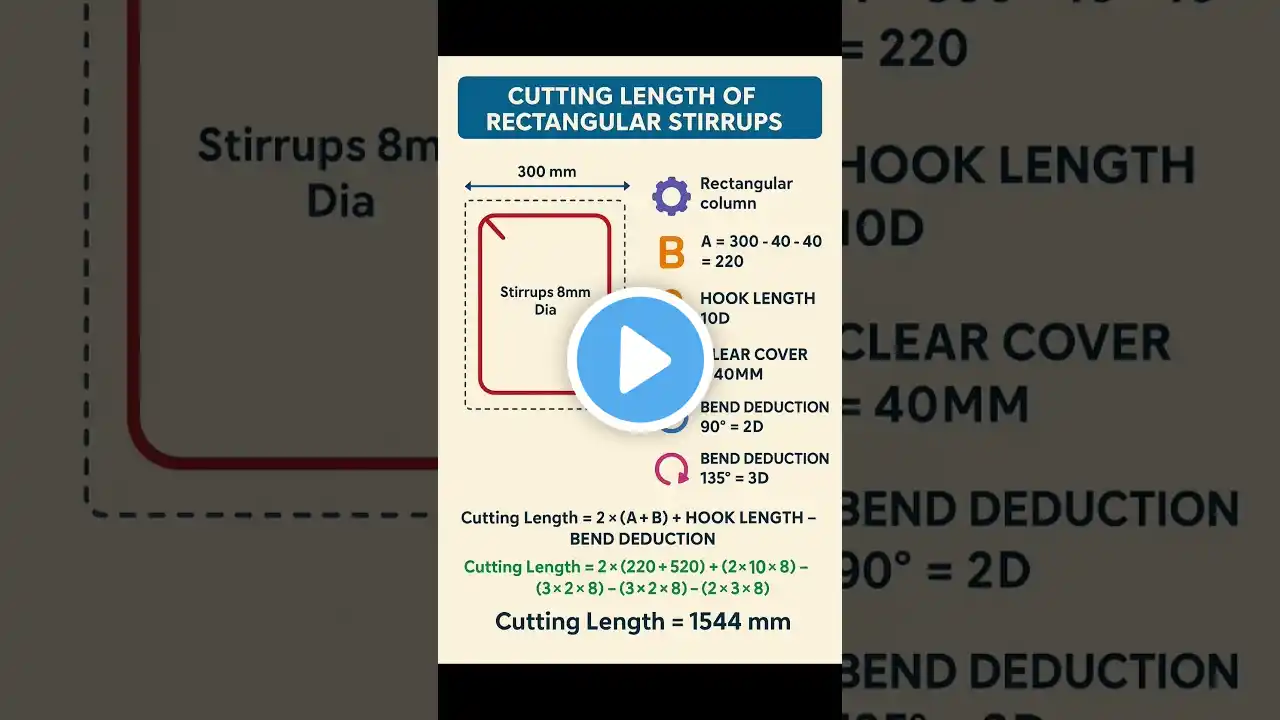

🛠️ 𝗕𝗮𝗿 𝗕𝗲𝗻𝗱𝗶𝗻𝗴 𝗦𝗰𝗵𝗲𝗱𝘂𝗹𝗲 𝗙𝗼𝗿𝗺𝘂𝗹𝗮𝘀 🛠️ Welcome to this comprehensive guide on Bar Bending Schedule (BBS) formulas! 📏✨ In this video, we’ll explore the essential calculations, standard practices, and key formulas used to create a Bar Bending Schedule. Understanding these concepts is crucial for every civil engineer and contractor. Let’s dive in! 🚀🧱 ═════════•°•📐 °•═════════ 🔶 𝗪𝗵𝗮𝘁 𝗶𝘀 𝗮 𝗕𝗮𝗿 𝗕𝗲𝗻𝗱𝗶𝗻𝗴 𝗦𝗰𝗵𝗲𝗱𝘂𝗹𝗲? 🔶 ✨ The Bar Bending Schedule (BBS) is a detailed list of reinforcement bars with information about their size, shape, length, and quantity required for construction. It helps ensure accurate estimation and efficient management of steel reinforcement. 🔸 𝗜𝗺𝗽𝗼𝗿𝘁𝗮𝗻𝗰𝗲 𝗼𝗳 𝗕𝗮𝗿 𝗕𝗲𝗻𝗱𝗶𝗻𝗴 𝗦𝗰𝗵𝗲𝗱𝘂𝗹𝗲 🔸 📌 Accurate Estimation: Provides precise quantities and dimensions of steel required. 📌 Cost Efficiency: Minimizes wastage and helps in budgeting materials effectively. 📌 Time Management: Speeds up construction activities with organized planning. ═════════•°•🔧 °•═════════ 🔹 𝗞𝗲𝘆 𝗧𝗲𝗿𝗺𝘀 𝗶𝗻 𝗕𝗮𝗿 𝗕𝗲𝗻𝗱𝗶𝗻𝗴 𝗦𝗰𝗵𝗲𝗱𝘂𝗹𝗲 🔹 ✨ Before diving into the formulas, let's understand some basic terms used in BBS: 📌 Straight Length: Length of a bar without any bends. 📌 Bend Deduction: Reduction in length due to bending, usually measured in diameters. 📌 Development Length: Extra length of bar provided to make a secure bond with concrete. 📌 Hook Length: Additional length at the end of bars to secure them in concrete. 🔸 𝗙𝗼𝗿𝗺𝘂𝗹𝗮 𝗳𝗼𝗿 𝗕𝗮𝗿 𝗟𝗲𝗻𝗴𝘁𝗵 🔸 📌 Straight Bar Length = Total length as per drawing 📌 Bent Bar Length = Sum of all straight lengths + Bends (considering bend allowances) 📌 Hook Length = 9d (for a 90° bend) and 16d (for a 180° bend), where d is the bar diameter ═════════•°•📏 °•═════════ 🔶 𝗖𝗮𝗹𝗰𝘂𝗹𝗮𝘁𝗶𝗼𝗻 𝗙𝗼𝗿𝗺𝘂𝗹𝗮𝘀 𝗳𝗼𝗿 𝗕𝗮𝗿 𝗕𝗲𝗻𝗱𝗶𝗻𝗴 🔶 ✨ Let’s go through some common formulas used in BBS calculations: 🔸 𝟵𝟬° 𝗕𝗲𝗻𝗱 🔸 📌 Formula: Length of bend = 2 × π × R / 4, where R is the internal radius of the bend. 📌 Deduction for 90° Bend = 1d (where d is the bar diameter) 🔸 𝟭𝟴𝟬° 𝗕𝗲𝗻𝗱 🔸 📌 Formula: Length of bend = π × R, where R is the internal radius of the bend. 📌 Deduction for 180° Bend = 2d 🔸 𝗦𝘁𝗶𝗿𝗿𝘂𝗽 𝗟𝗲𝗻𝗴𝘁𝗵 𝗖𝗮𝗹𝗰𝘂𝗹𝗮𝘁𝗶𝗼𝗻 🔸 📌 Formula: Perimeter of stirrup + Total Hook Lengths - Bend Deductions ✨ For a rectangular stirrup: Total Length = 2 × (L + B) + 2 × Hooks - 4d (for 4 corners with 90° bends) Where L = Length, B = Breadth ═════════•°•⚙️ °•═════════ 🔹 𝗕𝗕𝗦 𝗖𝗼𝗹𝘂𝗺𝗻𝘀 𝗮𝗻𝗱 𝗗𝗲𝘁𝗮𝗶𝗹𝘀 🔹 ✨ A standard BBS includes these columns: 📌 Bar Mark: Unique identification number for each bar. 📌 Diameter: Thickness of the bar (in mm). 📌 Shape Code: Type of bar shape (like straight, L-shape, U-shape). 📌 Cutting Length: Length of bar after considering bends and hooks. 📌 Quantity: Total number of bars required. 📌 Weight: Weight per meter based on diameter (using the formula: Weight (kg/m) = d² / 162). 🔸 𝗕𝗮𝗿 𝗖𝘂𝘁𝘁𝗶𝗻𝗴 𝗟𝗲𝗻𝗴𝘁𝗵 𝗖𝗮𝗹𝗰𝘂𝗹𝗮𝘁𝗶𝗼𝗻 🔸 Total Cutting Length = (Straight Length) + (Hook Length) + (Bend Length) 📌 Ensure that all allowances and deductions are considered based on bending standards. ═════════•°•💡 °•═════════ 🔹 𝗧𝗶𝗽𝘀 𝗳𝗼𝗿 𝗔𝗰𝗰𝘂𝗿𝗮𝘁𝗲 𝗕𝗕𝗦 🔹 ✨ To create an accurate BBS, follow these tips: 📌 Understand the Drawing: Carefully study structural drawings before preparing BBS. 📌 Use a Standard Format: Follow standard BBS formats to avoid confusion on-site. 📌 Double-Check Formulas: Verify each calculation to eliminate errors. 📌 Include Reinforcement Details: Make sure to include all bar details such as lap lengths, cover, and spacing. 🔸 𝗔𝗱𝗱𝗶𝘁𝗶𝗼𝗻𝗮𝗹 𝗣𝗼𝗶𝗻𝘁𝘀 𝗳𝗼𝗿 𝗘𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆 🔸 1️⃣ Minimize Wastage: Plan bar lengths efficiently to reduce scrap. 2️⃣ Label Clearly: Mark each bar for easy identification during construction. 3️⃣ Maintain Quality: Ensure the use of high-quality steel for reinforcement. ═════════•°•📐 °•═════════ 📢 𝗤𝘂𝗲𝘀𝘁𝗶𝗼𝗻𝘀 & 𝗙𝗲𝗲𝗱𝗯𝗮𝗰𝗸 💬 Did you find this guide on Bar Bending Schedule formulas helpful? Drop your questions or thoughts in the comments below! 💭👇 If you enjoyed this content, don’t forget to like and subscribe for more in-depth construction and engineering tutorials! 🚀✨ ═════════•°•⚙️ °•═════════ 📌 #BarBendingSchedule #BBSFormulas #CivilEngineering #ReinforcementDetails #MirzaJahanzaibZameer