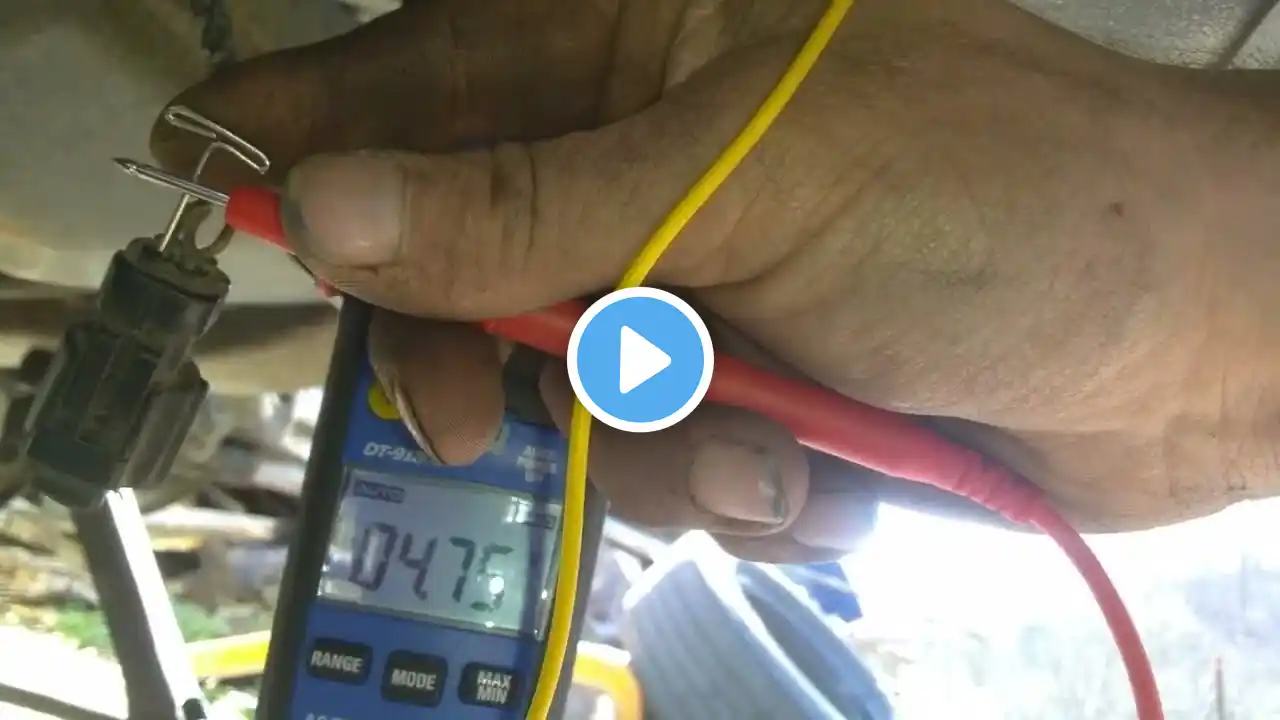

Ford AC pressure switch / pressure transducer testing w/ multimeter. How to bypass a pressure switch

How to troubleshoot pressure switches and pressure transducers without a wiring diagram on any make or model vehicle. Doesn't matter if it's 134a or 1234yf, automotive manufacturers use these switches to control the compressor clutch and prevent damage to the compressor. Do NOT just jump out a pressure switch without checking pressures first and making sure that the system is operating properly and do NOT just leave a pressure switch jumped out. You can have a leak or a restriction in the future and cost yourself alot of money, a $10-100 pressure switch is alot cheaper than a $800+ compressor and air conditioning system component change out. Also these switches and transducers can be used on the low side or high per manufacturers specifications. If it has 2 wires more than likely is a pressure switch which uses refrigerant pressure to open and close the switch based off a pre determined pressure for which the switch opens and kills power to the circuit. A pressure transducer works more like a potentiometer, the circuit has 3 wires. A 5v reference, signal wire, and ground. The 5v enters the transducer on the reference, the switch then adds certain amount of resistance on the 5v which knocks it down to a lower voltage which is returned to the PCM or a module which is then interpreted to be a suitable or unsuitable pressure. The PCM or module will either allow the ac compressor clutch to engage or disengage based off that info. Pressure transducers also allow the PCM or module to see how well the refrigerant circuit is working. Thanks for watching. Don't forget to like and subscribe. I am NOT liable for any damages, injury's, third party injury's, or death. This is video is for educational purposes only, I am in no way telling you to do this at home. This video shall not be reproduced without my consent